CPS Products

Citadel 8200

Chemical Resistant Epoxy

8200-HD offers the most extreme chemical resistance; making it perfect for areas subject to caustic washdowns. 8200-HD also withstands mechanical abuse from steel wheeled traffic. Essentially odorless, 8200-HD is suitable for food and beverage facilities.

- For extremely high chemical resistance, especially for alkalis and acids common to the food & beverage industry

- Withstands mechanical abuse from steel-wheeled traffic

- Labor saver; high build in a single coat; "Contractor's Choice"

- VOC compliant with 100% solids and low odor for use in all regulated areas

- Can be used over 10 day old, damp concrete

- No primer necessary

- Tested in over 350 chemicals for one year immersion

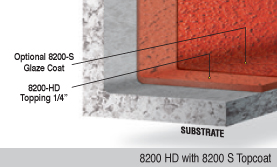

8200-HD (Heavy-Duty Topping)

Components Base, Activator, Aggregate

Turnaround Time 8-10 hours (foot); 24-48 hours (full); 4 days (chemical)

Primer None

Sealer Optional, None Required

Texture Various textures can be achieved by leaving the product uncoated or by using the appropriate topcoat

Application Type Type II

Film Thickness 125-250 mils

Gloss & Color Retention Good

Installation Temperature 65°–90°F (18°–32°C)

Chemical Resistance Severe

Abrasion Resistance Steel Wheel

Impact Resistance Severe

Thermal Shock Resistance Moderate

Key Industries/Typical Applications

Heavy-duty flooring for chemical processing, food & beverage and industrial manufacturing environments such as dairies, bottling, meat & poultry processing, breweries & wineries, processing plants, secondary containment, grain processing, trench liners and tank farms.

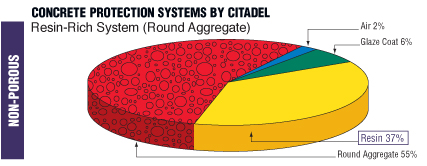

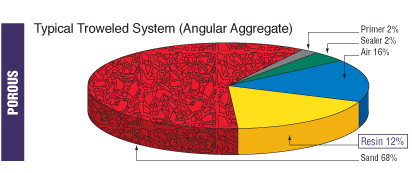

Resin-Rich vs. Troweled

Citadel's resin rich systems contain a much higher ratio of resin-to-aggregate than troweled systems, making it non-porous and exceptionally chemical resistant. Our resin-rich systems use a round aggregate which allows resin to flow between the particles

8200-HDV (Heavy-Duty Vertical Coating)

Application Type Type II

Film Thickness 125 mils

Gloss & Color Retention Good

Installation Temperature 65°–90°F (18°–32°C)

Chemical Resistance Severe

Abrasion Resistance -

Impact Resistance Severe

Thermal Shock Resistance Moderate

Key Industries/Typical Applications

Heavy-duty vertical coating for concrete or block walls in chemical processing, food & beverage and industrial manufacturing environments such as dairies, bottling, meat & poultry processing, breweries & wineries, processing plants, secondary containment, grain processing, trench liners and tank farms.

8200-TX (Textured Coating)

The TX formula utilizes a proprietary resin system to create a durable, textured, two-component, 100% solids anti-slip floor coating. Count on the advanced technology of Citadel 8200 TX for a textured floor coating that maintains its "like new" look. Ideal applications include high-traffic areas, areas requiring slip resistance or protection against chemicals and abrasion. 8200 TX can be easily combined with other systems, like 9000 System, or with additives like Aluminum Oxide for maximum performance and protection in your busy facility.

- Superior abrasion resistance

- Excellent chemical resistance

- Easy-to-mop and clean skid-resistant surface

- Textured finish minimizes flooring imperfections and provides anti-slip safety

- Can also be used as a vertical finish on concrete blocks

Application Type Type I

Film Thickness 14-16 mils

Gloss & Color Retention Better

Installation Temperature 65°–90°F (18°–32°C)

Chemical Resistance Mild to Moderate

Abrasion Resistance Rubber Wheel

Impact Resistance Mild to Moderate

Thermal Shock Resistance Mild to Moderate

Key Industries/Typical Applications

Textured floor coating for institutional, commercial & light manufacturing environments like laboratories, offices, corridors, locker rooms, shower rooms, restaurants, bathrooms, kitchens, cafeterias, schools, manufacturing, pharmaceutical areas & hospitals.

8200-S (Smooth Coating)

Application Type Type I

Film Thickness 16-50 mils

Gloss & Color Retention Better

Installation Temperature 65°–90°F (18°–32°C)

Chemical Resistance Moderate to Severe

Abrasion Resistance Rubber Wheel

Impact Resistance Mild to Moderate

Thermal Shock Resistance Moderate

Key Industries/Typical Applications

Floor coating for chemical processing, food & beverage and industrial manufacturing environments such as dairies, bottling, meat & poultry processing, breweries & wineries, processing plants, secondary containment, grain processing, trench liners and tank farms. Also used as a chemically resistant topcoat in heavy-duty and thermal shock environments.

8200-V (Vertical/Wall Coating)

Application Type Type I

Film Thickness 8-16 mils

Gloss & Color Retention Better

Installation Temperature 65°–90°F (18°–32°C)

Chemical Resistance Moderate to Severe

Abrasion Resistance -

Impact Resistance Mild to Moderate

Thermal Shock Resistance Moderate

Key Industries/Typical Applications

Vertical coating for concrete or block walls in chemical processing, food & beverage and industrial manufacturing environments such as dairies, bottling, meat & poultry processing, breweries & wineries, processing plants, secondary containment, grain processing, trench liners and tank farms.

8200-CB (Cover Base)

Application Type Type II

Film Thickness 1/8"-1/4" w/ 1½" radius

Gloss & Color Retention Good

Installation Temperature 65°–90°F (18°–32°C)

Chemical Resistance Severe

Abrasion Resistance Steel Wheel

Impact Resistance Severe

Thermal Shock Resistance Moderate

Key Industries/Typical Applications

Cover base for chemical processing, food & beverage and industrial manufacturing environments such as dairies, bottling, meat & poultry processing, breweries & wineries, processing plants, secondary containment, grain processing, trench liners and tank farms.

Latest News

How to Maintain Your Concrete Grinder

Gain Customers and Referrals in 4 Easy Steps

Ready for the Summer Rush? 4 Ways to Prepare

6 Cold Weather Safety Tips for Installers

How to Remove Salt Stains from Concrete

Testimonials

Every time I call I get to talk to someone, and I always have an answer within 20 minutes. That's awesome.

Client: Terry C.